Essential Oil Distillers and Kits for making DIY essential oils at Home

Are you searching for the finest essential oil distillation equipment for your home arrangement? This guide cuts through the confusion to help you understand the key aspects that differentiate essential oil distillers and determine their suitability for your distillation projects. From material and capacity to ease of use, we will provide you with the critical insights necessary to make the right choice.

The Art of Distilling Your Own Essential Oils

Embarking on your home distillation journey begins with choosing the right apparatus. The distiller is the heart of your setup, the tool that transforms aromatic plants into precious oils. But not all distillers are created equal. It's crucial to consider the distiller's material and capacity and to understand how the steam distillation process works.

Distilling your own essential oils is exciting and rewarding. Sharing homemade oils with family, friends, and acquaintances gives you great pleasure and happiness. You can produce more than 2 ml of essential oils per 20 minutes and use them for aroma purposes, making handmade soaps and lotions, or for a side business.

Various distillers provide different levels of effectiveness and longevity, with the material being a crucial factor in determining this. While some distillers are made from durable stainless steel for longevity and ease of cleaning, others feature premium, heavy-gauge copper for their antimicrobial effects.

Copper, known for its superior heat conductivity, is often preferred. This metal ensures efficient steam distillation and imparts antimicrobial properties, making it ideal for medicinal purposes.

We usually recommend a basic set as the "starter" or a gift for someone wanting to try a new hobby. This set includes the basic things to start the distillation process and get the first results in a few minutes.

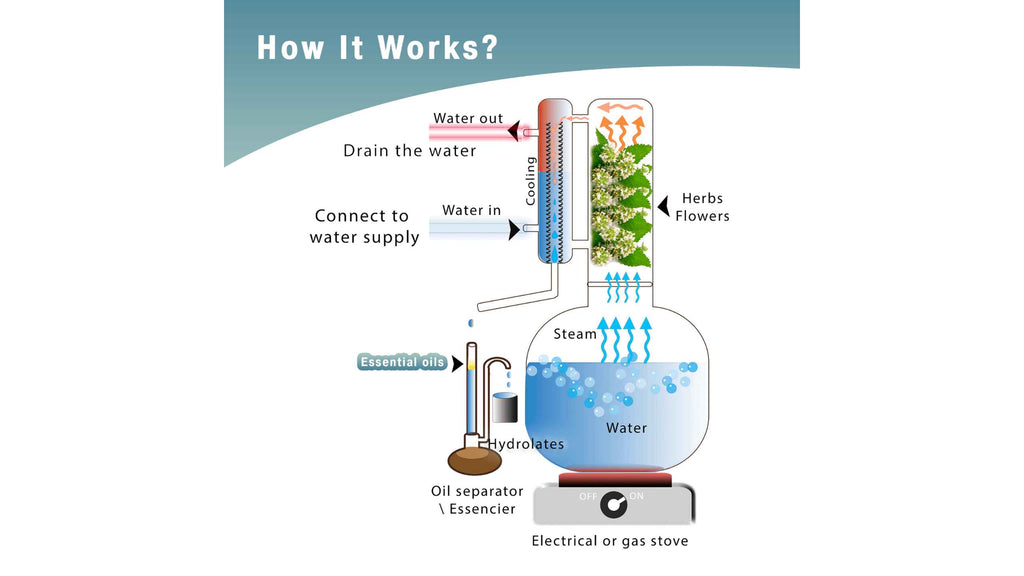

How do steam distillers for essential oils work?

When water steam rises, it takes essential oil particles from the raw material. Subsequently, the steam goes through the steam pipe to the cooler.

Cool water comes into the cooler(condenser) from the bottom part and cools down the tubes installed inside the cooler. The steam passes inside the same tubes and consequently gives its temperature to the water. Hot water leaves the cooler from the upper part and cooled hydrosol drops from the extended tube of the cooler.

Capacity Considerations: Matching Size with Yield

Capacity, or the quantity of plant material it can accommodate, is another critical factor to consider when choosing your distiller. The still size should match the availability of your plant material and intended use, such as producing essential oils for personal use or selling.

For example, a larger one would still be more profitable if you have a lavender farm. However, if you only have a small herb garden, a smaller still ranging from 5L to 20L would suffice. Remember, it's not just the size of the Boiler but the volume of the distillation column that matters when it comes to yielding essential oils.

Sets and models of our Essential oil distiller kit

We have basic, premium, and professional sets. The basic distiller set includes everything you need to start the process and get the first results in a few minutes. It includes everything you need to start distillation and make essential oils at Home or in your workshop, including a step-by-step guide to help you distill your oils.

The package includes everything you need for the distillation process: a Boiler, column, tri-clamp, silicone gasket, and sieve.

The premium oil distiller set includes the main parts and additional bottles that facilitate the distillation process. You don't need to worry about vessels or pipettes; we put them inside.

The advanced essential oil distiller set includes everything you need to start distillation. However, as you mentioned, it's an advanced set and costs more than BASIC and PREMIUM. The main feature is an extra column (extension/basket*). One column can multiply your results!

Package includes: Boiler, flavoring column, sieve, gasket(2), clamp(2), tap adapter, water hose, pipette, a glass tube(2), oil separator, thermometer, pipette, bottles(5,(2)10,(2), glass funnel, an extra column.

As you probably noticed, there is a difference in the column of distillers. For example:

- The column of still 4 liters, with this volume of the column, you can make approx. 20 ml of rosemary oil \ per 20 min.

- For instance, if we take a premium or basic set (with 2 l column), we can expect just 10 -12 ml of rosemary oil per 20 min.

In each package, we put a step-by-step guide to help you distill your oils. Also, you can watch our video on the channel CopperPro.

We take great pride in offering essential oil distillers. Our Distillers are carefully handcrafted using exclusively premium, heavy-gauge copper and lead-free soldering. They are not only beautiful to display in your Home or workshop but also completely functional.

Why copper essential oil distiller?

- Copper distillers provide the best heat conductivity among all other materials, 25 times better than stainless steel. The heat is distributed evenly during distillation to ensure an essential oil yield.

- Copper distillers do not break or rust and can, therefore, be stored away for a very long time. However, the material must be thoroughly dried beforehand to avoid the formation of a toxic green patina. As opposed to the green patina, the dark brownish patina that develops after a while is a natural protection against rust and is harmless to health.

- Copper is an essential oil distiller for medicinal purposes, e.g., to produce remedies. Copper is best suited for its antimicrobial effects. It naturally removes harmful fungi, germs, and bacteria that are not supposed to remain in the distillate. That's why copper has a good standing in the production of perfumes, hydrosols, and essential oils. Especially for remedies, it is important to mention that copper is not magnetic and, therefore, will not negatively impact the curative power of herbs or other plant material.

What's the point of buying the essential oil distiller

Owning an essential oil distiller kit comes with a myriad of benefits. Here are some of them:

- It enables you to create your unique blends of essential oils.

- It makes the whole process cost-effective and sustainable.

- You have complete control over the ingredients, ensuring their purity.

- You can customize your oils according to your personal preferences.

Whether you want to distill essential oils for personal use or turn it into a side business, owning a distiller allows you to tailor your production to your needs. And the best part? You get to share this rewarding hobby with your family and friends, spreading the joy of essential oils.

If you are looking for a productive and durable distiller, then you have found what you are looking for. The main feature of our essential oil steam distillers is that we developed them with an expanded column/basket for plants. This means that despite having a small distillation boiler volume, you will get a decent amount of essential oils (more than 2 ml per 20 min).

There are no stainless steel or glass distillers analogs with such efficiency.

Frequently Asked Questions

How to choose a distiller for essential oil?

It is best to choose a distiller based on the amount of raw materials you have or the amount of essential oil you want to receive. All our distillers differ in the size of the column for raw materials and the Boiler for water. The larger the distiller, the more essential oils and hydrosols you can get at one time. We have stills with the following volumes of the column:

- 1 l - approx. yield of rosemary, lavender, fresh mint EO - 4-5 ml

- 2 l - approx. yield of rosemary, lavender, fresh mint EO - 9-10 ml

- 4.5 l - approx. yield of rosemary, lavender, fresh mint EO - 18-22 ml

- 8.5 l - approx. yield of rosemary, lavender, fresh mint EO - 35-40 ml

- 18 l - approx. yield of rosemary, lavender, fresh mint EO - 80-90 ml

For more information and to view our products, you can visit this page for the most popular small models with a 2 liters column for raw materials, and this page for the largest model with an 18 liters column for raw materials.

What is the difference between a distiller for the production of oil and a distiller for the production of hydrosol?

The difference between the apparatus for essential oil and hydrosol production is the size of the column. A column with a larger volume is needed for oil production because more raw materials are required. Apparatuses with a small column volume will not produce essential oils, only hydrosols. The essential oil apparatus is also supplied with a separator to separate the essential oil from the hydrosol. All essential oil distillation equipment can produce both essential oils and hydrosol. Only hydrosols can be made on the hydrosol machine.

How much essential oil will you get?

The yield of essential oil depends on many factors. The main ones are the type of raw material used and the size of the apparatus. All our distillers differ in the size of the column and the water boiler. The larger the distiller, the more essential oils you can get at one time. Also, the output depends on the plant material used and its essential oil content. To check how many essential oils your plants contain, you can write the name of the raw material in a search engine and the phrase Essential Oil Output. We also recommend reading this article. But even if you choose one particular plant material, the yield and quality of the essential oil depend on parameters such as the age of the plant, the time of day when the raw material was harvested, the amount of sun the plant received that year, and the quality of the soil. Regarding the age of the plant, it is believed that it only gives a higher yield in the 2nd year.

What is the difference between an Essential Oil Distiller and an Essential Oil Extractor?

These models have the same water boiler capacity and differ in the size of the feedstock column. The essential oil extractor has a larger column for raw materials, allowing more feedstock and more essential oils to be obtained in one distillation process.

How much water to pour into the Boiler?

If you are producing essential oils and hydrosols, the water tank must be filled, as 80% of the water poured into the Boiler can be extracted as hydrosol. If you only produce essential oils, you can fill the water tank not completely, because essential oils do not require a large amount of water.

What should the temperature be?

Set the heat to the highest setting until the water begins to boil. You can reduce it later, but keep the water boiling throughout the process. Turn on the distiller cooling. This can be done once the water reaches 70°C/160°F. Maintain temperature between 95-98°C/203-208°F for maximum essential oil yield.

![Essential oil extractor 0.53G (2L) - [Premium Kit] - Copper Pro](http://copper-pro.com/cdn/shop/files/essential-oil-extractor-053g-2l-premium-kit-127057.jpg?crop=center&height=1280&v=1740390471&width=1280)

![Essential oil extractor 0.53G (2L) - [Premium Kit] - Copper Pro](http://copper-pro.com/cdn/shop/files/essential-oil-extractor-053g-2l-premium-kit-165442.jpg?crop=center&height=1080&v=1740390491&width=1080)